In December 2019, Devico released its first downhole gyro system. Less than three years later, an astonishing 1000 DeviGyro units have been produced, far exceeding Devico´s expectations, and clearly documenting how the industry was ready for a new and innovative gyro system.

In this article, Alex Butler, our International Sales Manager, gives you direct insight into the top five reasons why so many companies are choosing DeviGyro.

1. Versatility is key

Firstly, DeviGyro is an advanced, miniature rate gyro survey instrument designed for recording precise downhole navigational data, as quickly as possible for a large variety of mining and civil drilling applications.

Incorporating state-of-the-art gyroscope technology and proprietary navigational algorithms, the DeviGyro precisely detects and quantifies any movement the instrument is subjected to as it traverses the drill hole. Providing highly accurate, repeatable data at any angle and location on the planet.

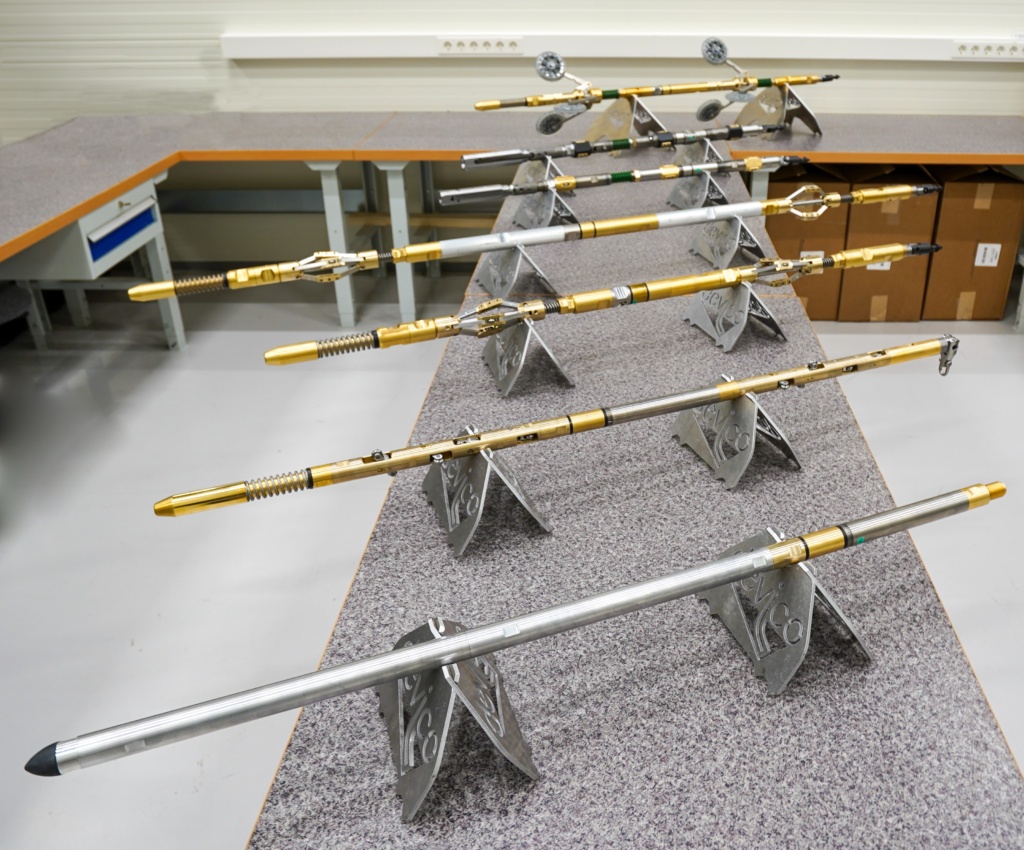

The physical DeviGyro system is best described as ultra-versa-tile. With the complete instrument being so small and capable, we have been able to develop a leading range of interchangeable, purpose-built running gear configurations. Each configuration suits specific drilling applications for length, weight, material, centralizer type and range. This modular type of offering has resulted in the DeviGyro being widely accepted as the preferred solution worldwide for many leading companies in the mining and civil space.

It is also worth mentioning that we do not only supply the DeviGyro for standard borehole surveying requirements, but it is also integrated with Devico’s Directional Core Drilling (DCD) barrel, DeviDrill, and in the new non-coring directional drilling barrel, DeviDrill RSS.

2. More in the running gear than meets the eye

For Devico, survey tool running gear assemblies are much more than just pressure-proof instrument containers. Over the past decade, we have developed several leading running gear technologies that have proven to both enhance survey accuracy and survey tool reliability.

One example is the Brilliant Blue Technology (BBT) activation and patented Bluetooth wireless antenna system, enabling quick set up, data transfer and wireless download without cables or having to open the instrument.

Another example is our patented low friction wheel-based helix centralizer systems that combat residual bias and greatly improve accuracy.

In addition, we have advanced vibration damping in several steps, both in axial and radial directions to maximize robustness.

The best example of what we mean by ‘purpose-built running gear’ is the DeviGyro Overshot Xpress (The OX), our overshot survey solution for diamond core drilling, proven to increase drilling productivity compared to conventional overshot survey systems.

Overshot surveying is a highly beneficial survey method for diamond core drilling, enabling surveys to be conducted while retrieving core tubes, effectively integrating surveying into the drilling process, and maximizing available drilling time per shift.

Manual handling and operator safety, however, are key factors that also must be considered.

Unlike other overshot survey tools on the market with typical lengths of several meters, the OX is purpose-built for this application. It is not a survey tool that is just adapted to be used in over-shot surveying mode, it’s built just for it.

With a short 1.2 m (3.94 ft) length and 7.4 kg (16.3 lb) weight, the OX is the ideal overshot surveying solution for both surface and underground diamond core drilling applications, and especially beneficial for surveying underground and in other confined space environments. Not only maximizing the beneficial productivity gains that come with overshot surveying, but safer operation and minimal impact on the operator as well.

All DeviGyro components are designed, built, and tested in-house at our headquarters in Norway. All stages of this work are performed by qualified mechanical and electrical engineers with many years of experience and over 90% of all materials used are sourced locally. This is how we ensure quality control.

3. Extremely robust

All through the development process of the DeviGyro, a key element was to make a small, lightweight and nimble system that could be used in multiple applications. Not only does this give a system that is easier and safer to handle for the operator, but a key reason was also that a small and lightweight electronics and battery solution significantly contributes to robustness, because the size and weight of an instrument clearly correlate with shock resistance.

Additionally, the advanced damping technology we have developed for the various running gear configurations offers superior protection for the DeviGyro sensor compared to conventional, fully integrated survey tools.

As a result of these careful design considerations, the failure rate for the DeviGyro is extremely low (and significantly lower than our competitors’ products according to our clients). Even with so many units produced, only a handful of gyros have had to come back for repair. There have even been occurrences where, due to an incident during surveying, the running gear has come back severely damaged, but the DeviGyro instrument has been unharmed, and ready to be placed in a new running gear after an onsite calibration check.

Even in the toughest of drilling environments, such as drill and blast, reverse circulation, or the high impact method of overshot surveying, DeviGyro excels as an easy to handle and extremely robust survey tool, setting a new standard for what our customers can expect and saving time and money for everyone involved.

4. OTA (Over-The-Air) Programming

To enable continuous improvement and efficient delivery of all new functionality, our engineers developed the Android DeviGyro app with key parts of the intelligence of the system not in the instruments themselves, but in the subsequent processing of the data. The logic behind this is that it is much easier to update an app to add new features than it is to remotely update instruments that are deployed all around the world.

This system allows our customers to simply do the latest app update and obtain added functionality through OTA (Over-The-Air) programming. Hence a customer who has bought one of the first DeviGyro kits in 2019 has access to the same functionally as a customer who buys their tool next week. And at no extra cost. Effectively ensuring all DeviGyro customers take part in advancements.

One of the greatest updates so far is undoubtedly the introduction of ADE (Automatic Depth Estimation), which was released in mid-2022. ADE is a new function within DeviGyro that enables continuous borehole surveying without the use of a wireline counter. The depth is instead estimated from the instruments’ onboard sensors and new proprietary algorithms. This feature is free for all DeviGyro customers through a simple app update.

5. Taking the term ‘user friendly’ to the next level

Having developed borehole survey solutions for over 30 years, we know that ease-of-use is often more important to operators than most other survey tool features. For the DeviGyro we have put a lot of effort into developing a survey system which is guided via intuitive steps in the operating application, so that it does not take an expert to learn the application and get an optimal survey result. Simplicity is always at the forefront to minimize the room for confusion and guesswork. As a consequence of this, the feedback we often get from customers all around the world is that the DeviGyro is the easiest instrument to use on the market.

This point is well documented by the fact that the large majority of DeviGyro customers have been successfully onboarded with the product via a one-two-hour, remote, online training session only.

When it comes to pre-survey set up time, all DeviGyro kits are designed for easy assembly and quick activation. Resulting in an extremely efficient survey process and time savings.

Finally, the onsite processing, transfer, and management of bore-hole survey data are more streamlined and user-friendly than ever with the combination of DeviGyro and DeviCloud.

In a nutshell, DeviCloud, our uncomplicated cloud-based platform, enhances the data transparency and quality of DeviGyro surveys.

Not only does it provide fast processing, instant QA/QC data analysis, comprehensive plotting and inspection parameters, along with advanced reporting functionalities, but all while supporting secure two-way communication between site and office. Making it possible to share and sync data directly to and from the handheld device at the drill site, with ease.

We see that this not only improves efficiency but provides stronger insight and ownership for everyone in the chain, from drill site to head office. In a way, this system is making survey data more democratic and transparent.

In summary

We see the success of the DeviGyro is mainly down to these points: the right tool for the job, built to last, advanced functionality, high quality and easy to use from start to finish. But we also recognize that without our people, our global network of employees and distributors having the experience, capability, and trust within the global market, the DeviGyro would not be as successful as it is. And for that, we are eternally grateful.

So, what’s next?

Well, despite proving that the DeviGyro is a leading solution for the large majority of drilling applications, we recognize that a north-seeking gyro could be preferred in some cases. And hence are currently launching the DeviStar north-seeking gyro. This new product, which is now being released gradually into selected markets, will complement our already strong portfolio of borehole surveying solutions.