Challenge

Unlike with our DeviDrill Directional Core Drilling technology, planning and executing a successful Navigational Drilling program are two different things. There is an ever-present risk that the downhole motor or wedge is not set or positioned correctly in the drill hole which can lead to periodically steering the hole in the wrong direction, wasted time, and re-work.

Also, when conducting a Navigational Drilling program there is generally more emphasis on time and productivity associated with daily costs, as the penetration rates are much slower during the process of making the alteration to the drill hole, then compared to the standard diamond core drilling process.

So, the challenge is obtaining accurate downhole navigation survey data in a timely matter, measuring the position of the down hole motor or wedge to ensure it is set and positioned correctly to plan, prior to beginning the alteration of the drill hole.

Solution

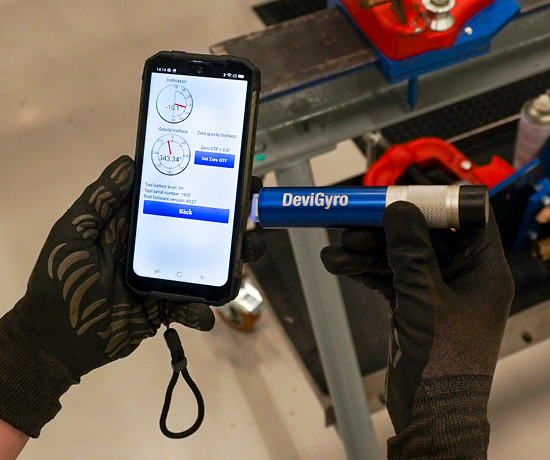

Utilizing a precise, dependable downhole navigation survey instrument, such as the DeviGyro RG40 Standard or DeviShot, with an Orientation Mule-Shoe is the solution.

The Orientation Mule-Shoe has a landing sleeve which enables the survey instrument to align with the correlating pin inside the downhole motor or wedge. This process establishes the “high-side tool-face” of the survey instrument, which is essential for knowing the orientation of the down hole motor or wedge.

Combined with the advanced DeviGyro and DeviShot technology, the drill crew are provided with the true orientation and positional data they need, in a timely manner, to be confident that are on plan and beginning the alteration correctly.

Benefits

- Quick set up time

- Record precise High-side tool-face data

- Automatic, instant At-Rig QA processing

- User-friendly, intuitive operating software

- True wireless – Connects when fully assembled

- Scandinavian made – Robust and reliable