There are three types of raise boring methods utilised in the mining production and development industry: Standard Raise boring, Down-Reaming, and Box-Holing. These all commence with the process of drilling a pilot hole (small diameter drill hole) from base level to the required level.

Once the pilot hole is achieved to plan, a large diameter reamer is attached and pulled-downwards or pushed-upwards (depending on the method) excavating the hole to the desired width.

Challenge

Factoring in the geological structure of the mine and the close proximity of existing underground works, the consequences of missing the target can be disastrous. So a high level of strict planning goes into all raise boring programs, with an extremely low tolerance for error. Therefore, due to the fact that every drill hole deviates, the key challenge with raise boring is drilling the pilot hole on target.

In addition, raise boring rigs are compact in height, the pilot holes are often vertical, and always drilled with short rods that have variable inner diameters. These factors all pose as further challenges when conducting downhole navigational surveys to measure the deviation.

Solution

Conducting precise downhole navigation surveys is essential for periodically monitoring the deviation of the pilot hole to ensure that it is on target, and additionally to verify the pilot holes definitive position once it is completed.

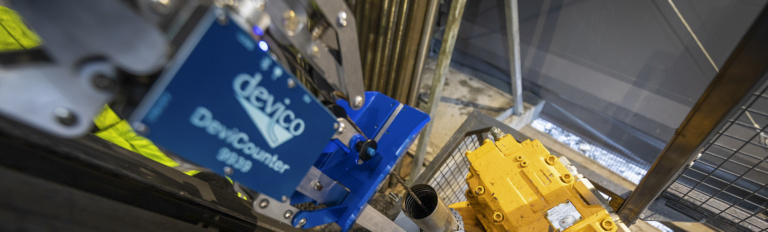

The solution is utilizing downhole navigation survey equipment that is compatible with raise boring rig sizes and rod types, which is the DeviGyro RG40 Standard. With innovative, variable running gear configurations and centralizer options, raise boring operators have the functionality they need to conduct high accuracy, efficient surveys.

Benefits

- Quick set up time

- User-friendly, intuitive operating software

- High speed, continuous surveying (up to 100m/min)

- Adjustable and adaptable centralizer options to fit a variety of diameters and shapes

- Seamless data transfer between site and office

- Repeatable precision at any angle

- Not affected by magnetics